Next case study

Dragon Shield Doors

View case study

You are using an outdated browser. Please upgrade your browser to improve your experience.

Cairnhill was contracted by BYLOR to fabricate, weld, paint, and deliver four Fixed Point Sleeves for Hinkley Point C nuclear power station. The project required precision engineering to meet stringent nuclear standards for one of Europe’s most complex infrastructure developments.

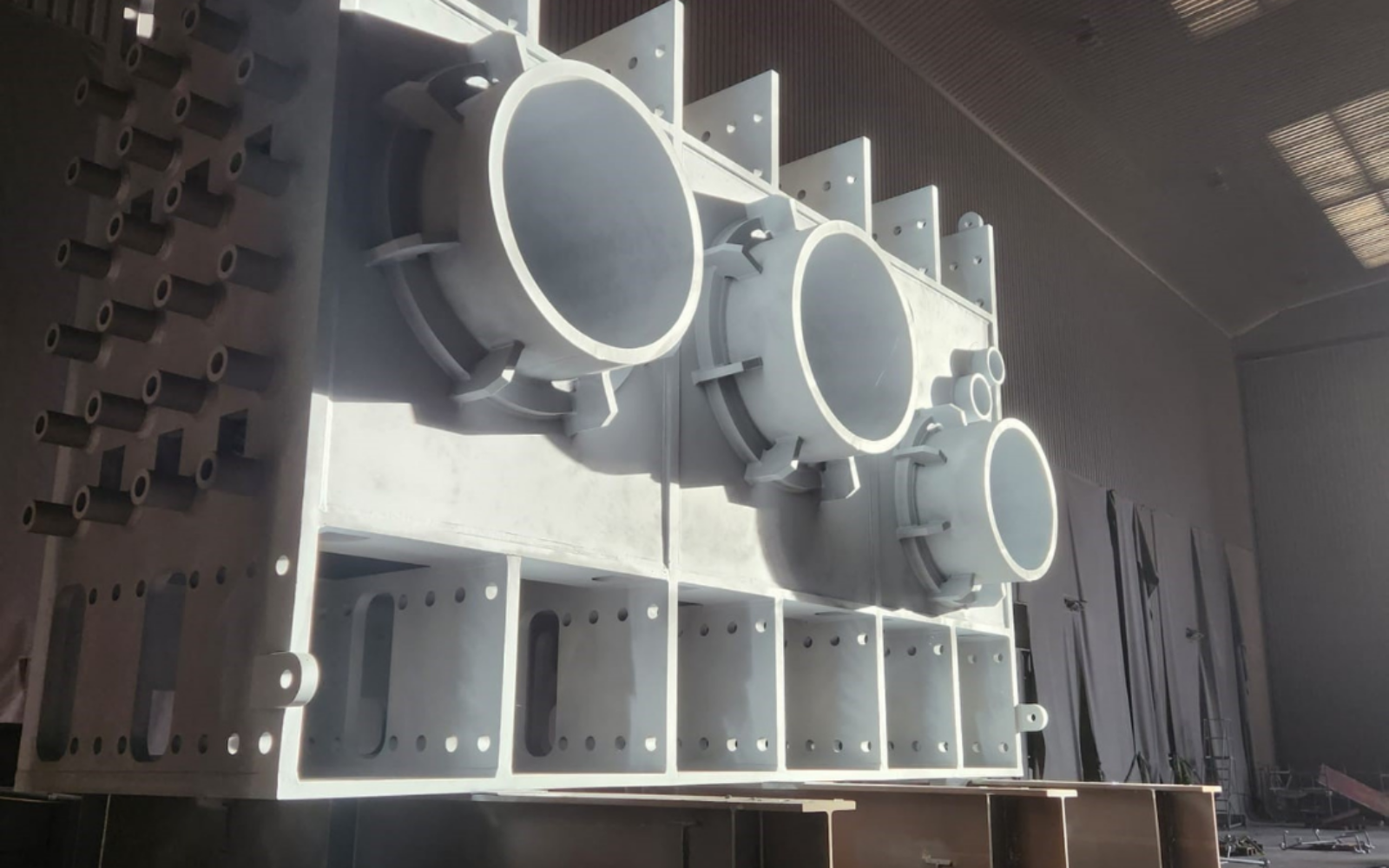

Contracted by BYLOR, Cairnhill were tasked with the complete fabrication, welding, painting, and delivery of 4nr Fixed Point Sleeves for Hinkley Point C’s nuclear power station.

Bouygues Travaux Publics (TP) and Laing O’Rourke, two of Europe’s most dynamic engineering and construction specialists, are working together in a joint venture named BYLOR to deliver the main civil engineering works at Hinkley Point C (HPC).

HPC will be the first new nuclear power station in a generation. Situated on the North Somerset Coast, it will power around 6 million homes with safe, secure, and low-carbon electricity. HPC is one of the largest and most complex projects in Europe and will take 10 years to complete. At the peak of construction, 5,600 people will be working onsite, and over the course of the project, 25,000 employment opportunities will be created.

Following the successful award of the £4 million, 2-year contract from BYLOR, Cairnhill was engaged to undertake the complete fabrication, welding, painting, and delivery of four 4nr fixed point frames for Hinkley Point C nuclear power station. These frames were integral to the installation process, playing a crucial role in the accurate positioning and securing of large components within the reactor buildings. Due to the technical specifications required for this type of infrastructure, the project demanded precision engineering.

Leveraging our expertise and precision when working within these sectors, each plate was cut to 60-65mm thick and was rolled in-house at our primary facility, Sun Works, Coatbridge, weighing approximately 60 tonnes each. After rolling, the components underwent extensive fabrication and welding processes, which were then transported to Cairnhill’s external contractors for heat treatment and surface finish processes. Once inspected and approved by our client, the fixed point sleeves were prepared for delivery to Hinkley Point C’s site.

Dragon Shield Doors

View case study